Community Tip - Did you get called away in the middle of writing a post? Don't worry you can find your unfinished post later in the Drafts section of your profile page. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Sheet metal Forming

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Sheet metal Forming

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Sheet metal Forming

Hi,

Creo-8

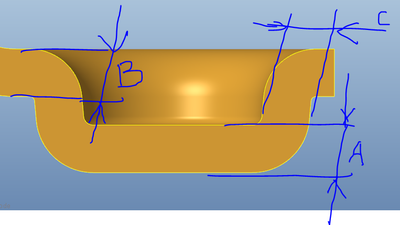

I would like to get sheet metal part with different thickness after forming ( coining ) operation

like the attached image below. Any idea

Solved! Go to Solution.

- Labels:

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

As Ben mentioned, sheet metal, while you can do punch and die operations, it will NOT (to my knowledge, at least with Creo 😎 thin the material out. You COULD do all the work in sheet metal, and then MANUALLY do a cut to thin the material out. OR try and do it as a regular solid model and make a shell feature with different thicknesses and it MIGHT work.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creo Sheet Metal is for press brake operations of uniform material thickness. Die forming is a different operation and cannot be done in the sheet metal module.

Model your section profile and revolve it will be the best method for creating the solid model boss/dimple to your required thicknesses.

You could model the cross-section into a press brake operation to get an approximate 'flat pattern' length, but die forming does not deform the material the same way a press brake operation does.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

As Ben mentioned, sheet metal, while you can do punch and die operations, it will NOT (to my knowledge, at least with Creo 😎 thin the material out. You COULD do all the work in sheet metal, and then MANUALLY do a cut to thin the material out. OR try and do it as a regular solid model and make a shell feature with different thicknesses and it MIGHT work.